Polyester fiber is one of the most commonly utilized fibers. Polyester fiber can be dyed by using disperse dyes. Polyester fiber is knitted into various types of clothing on circular knitting machines. Polyester fiber is dyed during or after yarn preparation and in fabric form. The fastness of polyester fiber having been dyed is excellent. The usage of fiber polyester fiber is increasing rapidly day by day.

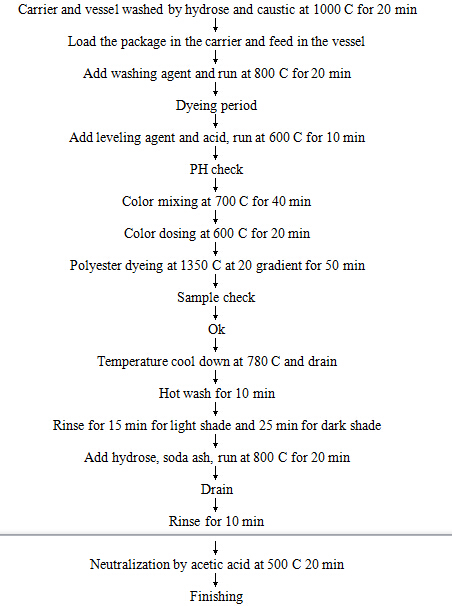

Dyeing sequence of polyester is given below:

The procedure of dyeing polyester fiber:

1.Carrier and vessel are washed by hydrose and caustic under 100℃ for 20 minutes.

2.Package is loaded in the carrier and feed in the vessel

3.Add washing agent and run under 80℃ for 20 minutes.

4.Adding leveling agent and acid, running under 60℃ for 10 minutes.

5.Checking PH.

6.Mixing color under 70℃ for 40 minutes.

7.Dosing color under 60℃ for 20 minutes.

8.Dyeing polyester fiber under 135℃ at 2°gradient for 50 minutes.

9.Checking sample

10.Cool temperature down to 78℃ and drain.

11.Washing in hot for 10 minutes.

12.Rinse for 15 minutes for light shade and 25 minutes for dark shade.

13.Add hydrose, soda ash and run under 80℃ for 20 minutes.

14.Drain

15.Rinse for 10 minutes.

16.Neutralized by acetic acid under 50℃ for 20 minutes.