Dyeing of polyester cotton which can be knitted into knitted fabrics on knitting machines also called as double part dyeing process is combined with polyester and cotton dyeing process. Polyester is dyed at first, followed by cotton.

Dyeing flow chart of polyester cotton is given below:

The followings are the procedures of dyeing polyester cotton:

1.Carrier and vessel are washed by hydrose and caustic under 100℃ for 20 minutes.

2.Load the package in the carrier and feed in the vessel

3.Adding wetting agent, antifoaming angent, sequestering agent and running under 60℃ for 10minutes

4.draining water solution

5.Adding wetting agent, sequestering agent, caustic soda and hydrogen peroxide. Run single yarn under 110℃ and double yarn under 115℃ for 20 minutes.

6.Draining

7.Adding peroxide killer and running under 90℃ for 10 minutes.

8.Checking peroxide in the package.

9.Draining

10.Checking sample and entering into dyeing

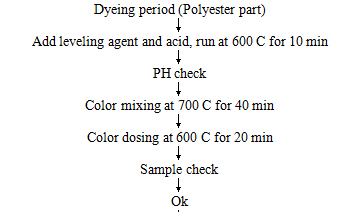

11.Adding leveling agent and acid, running under 60℃ for 10 minutes

12.Checking PH

13.Mixing color under 70℃ for 40 minutes

14.Dosing color under 60℃ for 20 minutes

15.Checking sample

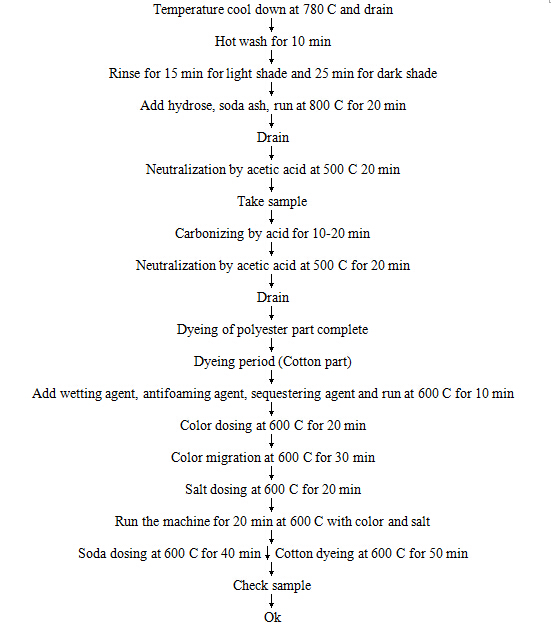

16.Cooling down to 78℃ and draining

17.Washing in hot water for 10 minutes.

18.Rinsing light shade for 15 minutes and dark shade for 25 minutes

19.Adding hydrose and soda ash, Running under 80℃ for 20 minutes.

20.Draining

21.Being neutralized by acetic acid under 50℃ for 20 minutes.

22.Taking sample

23.Being carbonized by acid for 10-20 minutes.

24.Being neutralized by acetic acid under 50℃ for 20 minutes.

25.Draining

26.Dyeing of polyester is completed.

27.Adding wetting agent, antifoaming agent, sequestering agent. Running under 60℃ for 10 minutes.

28.Dosing color under 60℃ for 20 minutes.

29.Migrating color under 60℃ for 30 minutes.

30.Dosing salt under 60℃ for 20 minutes.

31.Running the machine with color and salt under 60℃ for 20 minutes.

32.Dosing soda under 60℃ for 40 minute.

33.Dyeing cotton under 60℃ for 50 minutes.

34.Checking sample.

35.Draining

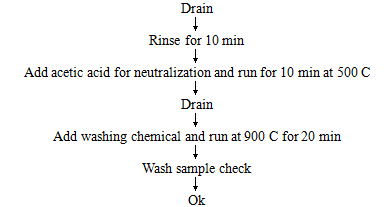

36.Rinsing for 10 minutes.

37.Adding acetic acid for neutralization. Running under 50℃ for 10 minutes.

38.Draining

39.Adding washing chemical. Running under 90℃ for 20 minutes.

40.Washing sample and checking

41.Draining

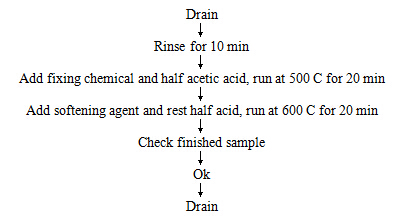

42.Rinsing for 10 minutes.

43.Adding fixing chemical and half acetic acid. Running under 50℃ for 20 minutes.

44.Adding softening agent and rest half acid. Running under 60℃ for 20 minutes.

45.Checking finished sample

Tips: Dyeing sequence of SVS is the same as P/C dyeing.