Recently, the traditional market in China textile city starts the sale of fall and winter knitted velvet fabric. Most of the products are presented with samples. The types of those products are continually increasing. As for those presented with prompt goods, they are mostly seen in some large stores. In autumn, the warp knitted velvet fabrics will start their sale in some regions. However, even in a slack market, there are also great products with firm price.

The second and third floor of eastern market is special business areas of knitted velvet. Among all products there, knitted fabrics like dyed spandex fabrics, Korean velvet fabrics, upright pile fabrics, corduroy fabrics, pleuche fabrics, velvet fabrics with high density, island velvet fabrics, coral velvet fabrics, short-pile velour fabrics, four-way spandex fabrics, cowboy spandex fabrics are sold at some regions. The price is firm while the orders generally require for medium or even small quantity.

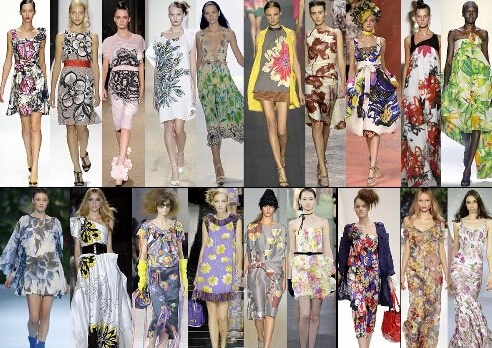

Types and pattern of jacquard coral fabrics, swiss dot fabrics as well as printed fabrics make some increase. These kinds of fabrics are usually used for manufacturing fashion women sweaters and suits. Therefore, they enjoy a good popularity among clothing manufacturers and the orders increase in some areas. Korean style fabrics also have an increasing orders amount for the new types.

Polyester semi-gloss FDY, DTY and POY thin printed double plush fabrics are generally presented with rose-red, pink, blue, green, light brown or nigger-brown hearts pattern on them. The sales of them increased in some large-scale stores.